Founders Dave & Suzanne Baker reviewing customer drawings, 1983.

Founded in 1970

3rd Generation, Family-Owned & Operated.

Honor. Dedication. Focus. Three key words that are at the heart of the Baker Manufacturing ethos. These words stem from the Baker team's devotion to their customers, and by constantly going "above and beyond" to deliver precision products on-time and on-budget.

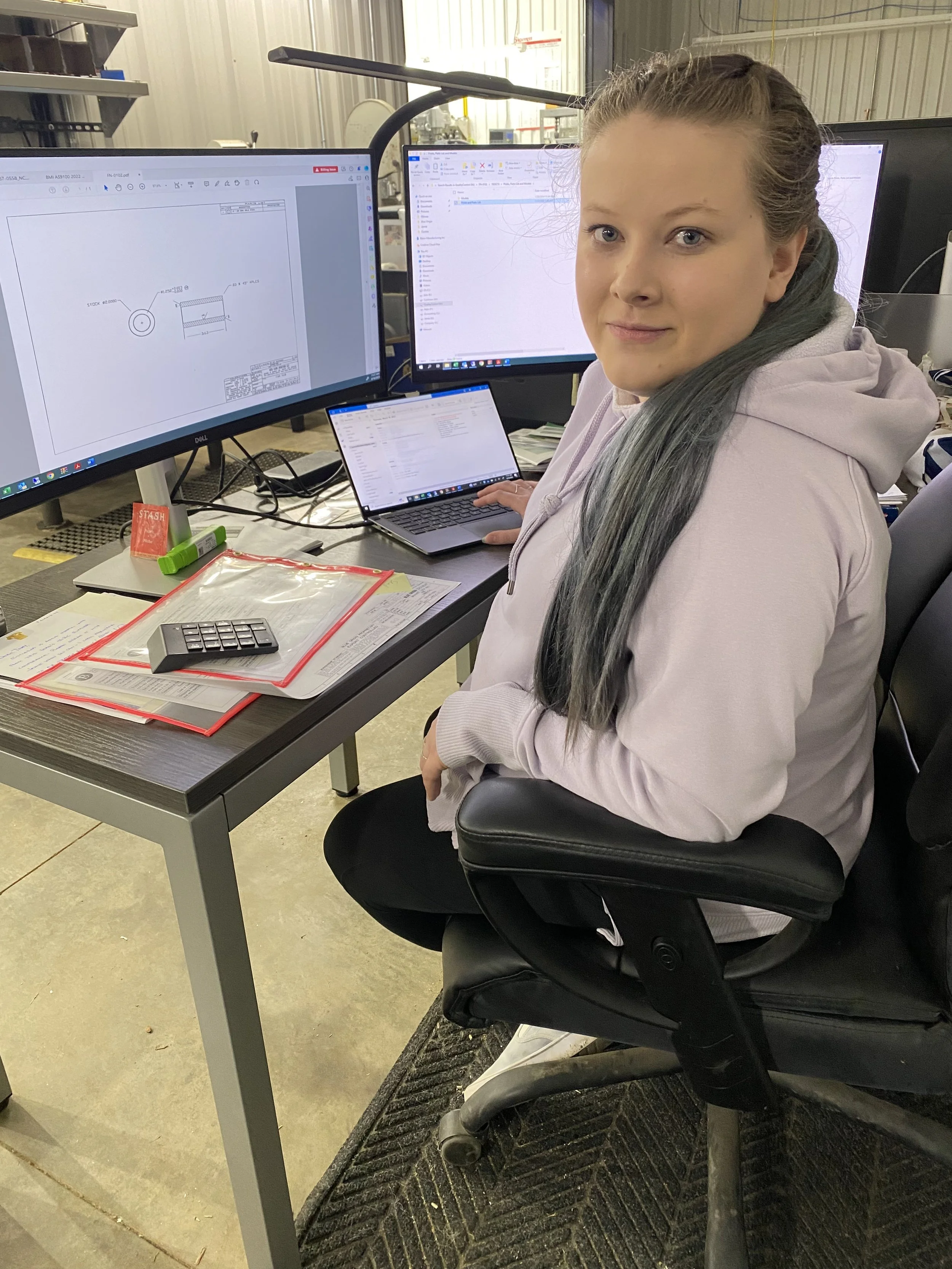

To ensure quality, Baker partners with you to develop and manage the entire production process. From engineering inquiry and understanding, through research and process development, to the manufacturing and quality assurance of parts, assemblies, and tooling, Baker knows that its products are critical to the customer's success.

For over 50 years, Baker has demonstrated its commitment as a proud, tier-one supplier to iconic jet airplane and space ship builders. And now submarines!

There's a reason we say, "At 32,000 feet, manufacturing excellence is the only option." Same at 50 atmospheres!

Baker Executive Team

-

Jamie Baker Smiddy

CHIEF EXECUTIVE OFFICER

As the leader of Baker’s third generation, Jamie oversees all aspects of the manufacturing business and customer support. Jamie is dedicated to the on-time and on-budget delivery of vital products to Baker’s customers. She manages Baker Manufacturing with diligence and care, driving best-value achievement throughout every company process and product. Jamie spent years at Baker, as Process Control Manager then CFO, before becoming CEO.

-

Tony Baker

CHAIRMAN & CHIEF ENGINEER

Tony grew up in Baker Manufacturing’s Tacoma machine shop. He is proud to champion the exacting standards and creative engineering required to help customers achieve new aerospace and maritime records. Tony loves machining and leads by example, perfecting his craft every day. Tony trains and mentors new generations of Baker CNC machinists and metal workers in the art and science of continuous quality improvement. Tony is a true Servant Leader!

The Baker team is honored to work with leaders in industrial machining and software.

Baker Partners

EMUGE FRANKEN

OKUMA

MLC-CAD SYSTEMS

FARO

BIG KAISER

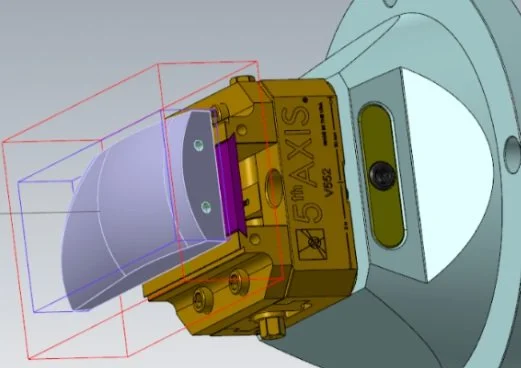

Our Partners contribute exciting innovations to many vital aspects of the Baker process.

MASTERCAM

MOLDPLUS

MITSUBISHI

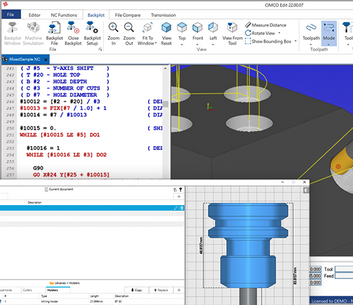

CIMCO

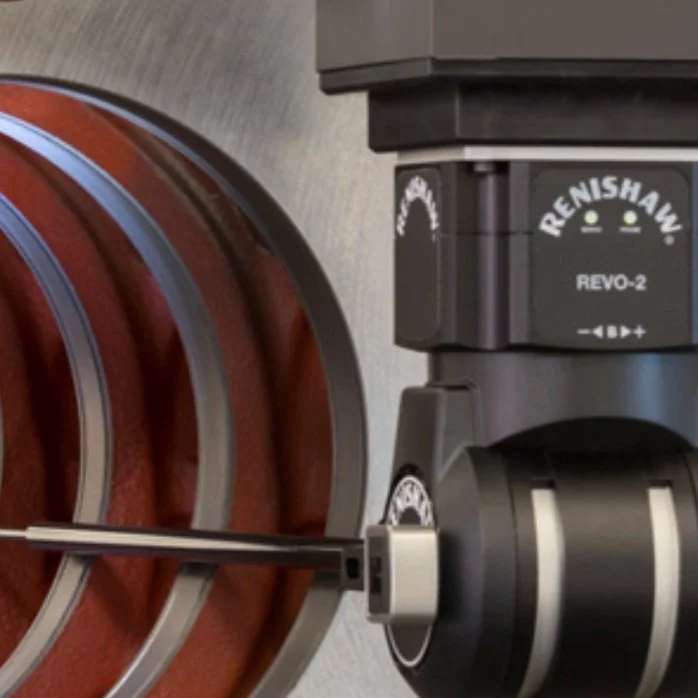

RENISHAW

Efficiency Means Productivity

-

REDUCE

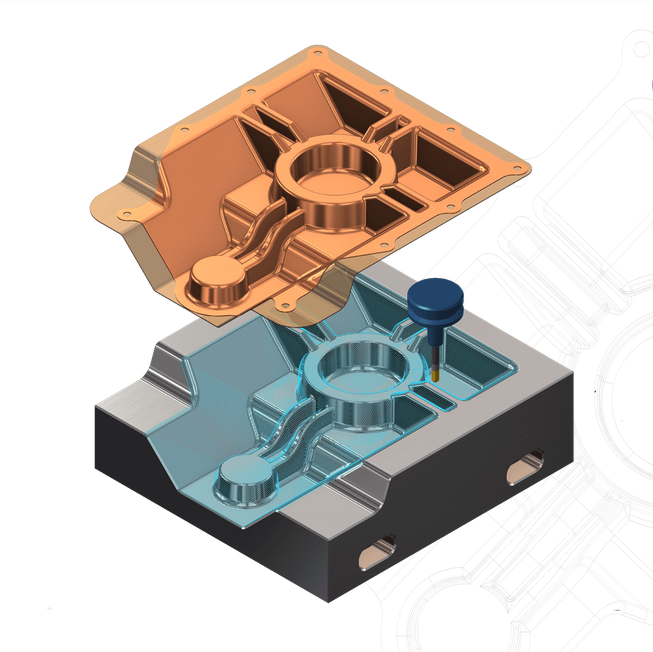

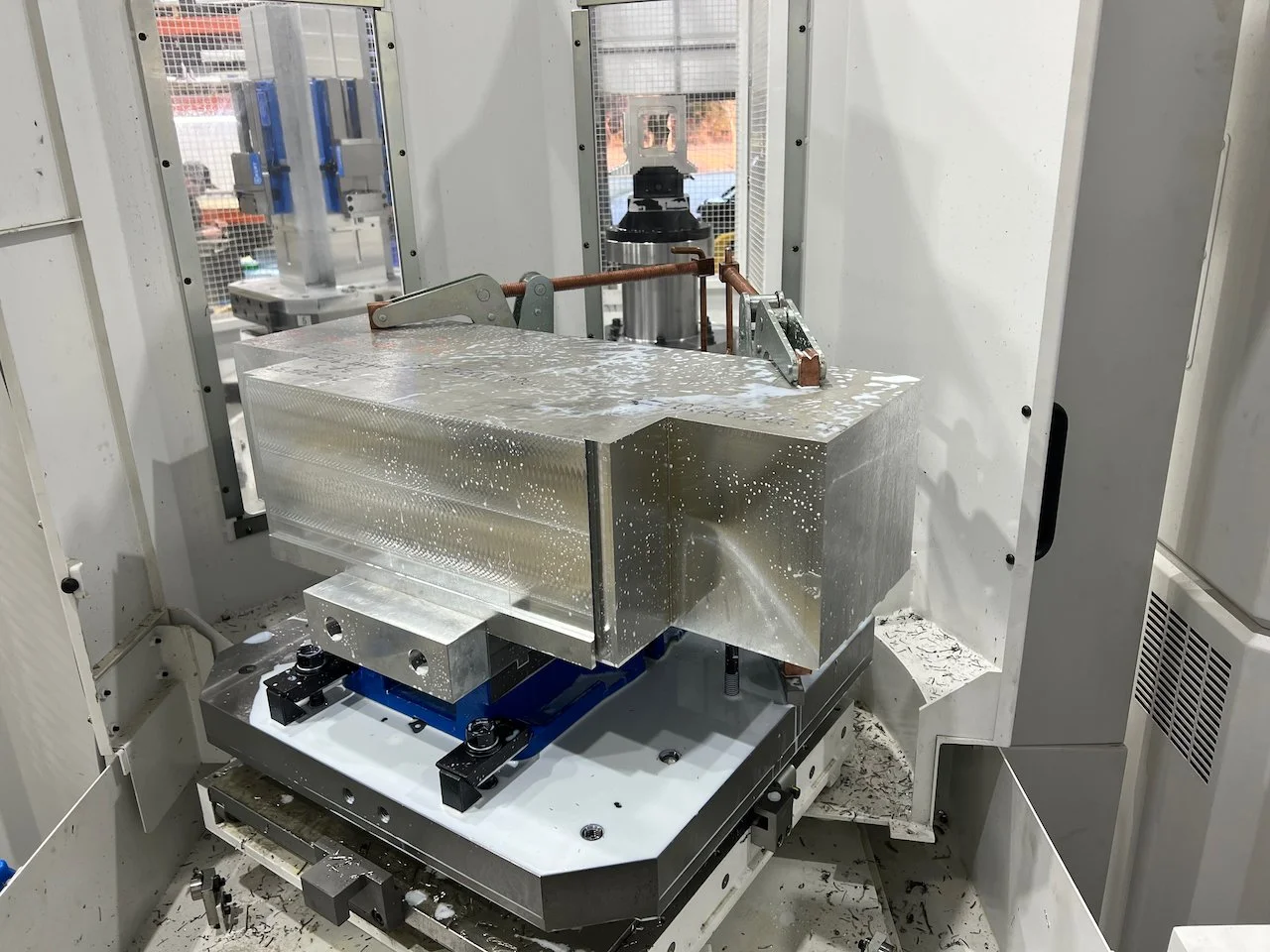

Key to efficient raw materials use is the reduction of waste - from the start of the manufacturing process. Before we even load a block of titanium on a CNC machine, we develop efficient tool paths with our Mastercam software to reduce wasteful cuts and get the absolute most out of the raw material.

Then, throughout the manufacturing process, we seek opportunities to reduce waste. From delivery driver routes to efficient packaging and partner work and, most importantly, our team members’ time, we maximize the use of every resource.

Here you can meet Bear the Wonder Dog, who loves to “guard” our materials!

-

RE-USE

By developing efficiency into the entire manufacturing process, we’re able to get more out of our raw materials than traditional methods. With commodity price volatility these days, we are focused on making sure that any leftover pieces of titanium or steel or aluminum are put to use on another project or used for R&D and apprentice training.

This philosophy of Re-use is directly related to our Reduce and Recycle strategies. We find opportunities for re-use everywhere. We re-use delivery packaging for shop floor processes, we re-use leftover pieces of raw materials, and we re-use tooling for different metals and machines.

-

RECYCLE

Modern machine shops recycle the "chips" that are the result of machining blocks of metal into precision parts. Those chips, or shavings, increase and decrease in value as the commodity markets change, but it’s always worth something. And we know, for example, that recycling aluminum can save on the order of 19 times the energy of making new aluminum from bauxite. So it pays to recycle - and it saves energy.

We work closely with regional materials recyclers to make sure metal shavings, metal packaging, and even some spent tooling is accounted for and placed into their process with the goal of creating a circular process to recycle as much as we can.

-

...And Use Clean Energy

With multiple CNC machining facilities, we’re somewhat dependent upon the local electricity and gas utilities for the “mix” of power sources we rely on for our industry. In the case of our Tacoma, WA facility, we get our electricity from Tacoma Power, which is proud to deliver nearly 98% carbon-free power to us, and we’re proud to use it!

We work with our local utilities to implement energy efficiency projects, like installing high quality LED lights, which also improves productivity. We also get help from the utilities and local governments with energy efficiency rebates so we can deliver better value from our supply chain to our customers every day.